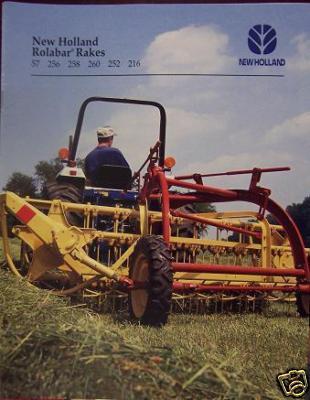

New Holland 258 Rake Rolabar Repair Manual

This is an ORIGINAL New Holland 216 Unitized Rake Operators' Manual (late 1986 printing, covers ALL models). This manual has super illustrations as well as having in-depth operating, maintenance, and specification information for these hard working NH rakes. The condition of the cover is very good with NO tears or tatters. The spline is tight and intact with NO splits. This manual contains 22 super clean pages that are also in perfect shape. Manual is in FINE overall condition.

Buyer agrees to pay $FREE for S & H. Thanks for viewing.Triple K.

I run two 258s on a tandem hitch and don't have many problems other than regular maintenance (broken teeth, etc.) Stack em is right on the gearbox oil. If the seals in the box are shot, then you can just squirt some grease in there and it should be fine. I believe cornhead grease is recommended since it will turn into more of a thick fluid as it is used and warms up. The 258 is just a wider version of the 256. I've thought about going to a rotary rake, but in my area they are about 3 times as much as a decent shape rolabar, so it doesn't make any sense for my small acreage. Plus all the rotary rakes I've seen at auctions here are pretty well used up.

In case you check the oil in the gearbox and find none, NH has not used oil in the gearbox for about 30 yrs. They have used regular grease in the gearbox since then. When you rebuild a gearbox, pack the bearings and use two tubes of grease to fill the box.

If you had an older rake with oil in it, then you also need to remove the 3/8' pipe plug with the cotter pin and replace it with a plug that does not have a hole to let water in. If your gearbox has oil in it, you will need to continue to use oil until you take the gearbox apart so the bearings can be packed with grease.

I run a 256 we bought new and a 258 I bought at an auction and went through (rebuilt bar bearings, spiders, new teeth, etc.) behind me pulled by a 'bridge hitch' (hydraulically swung hitch that goes over the front rake to the rear one) that I got at an auction for $150! It works great!

New Holland 258 Rake Serial Numbers

The 256 is an 8.5 foot rake, and the 258 is a little heavier built (older one) that's 9.5 feet. Works REAL nice taking about 17 feet at a time (overlap the rakes by about a foot so you don't miss anything). Plus, I can drop the 258 and pull it directly behind the tractor if I'm working in a small, irregularly shaped field.

In our area, parallel bar rakes are probably 50-60% of the rakes in the field, with the rest being wheel rakes. Most of the new rakes sold are wheel rakes. Rotary arm rakes are virtually unheard of around our parts. In fact I don't think I've ever seen one in the field in our part of the country (that I can recall). If you're picking one up at auction, be sure and check it out thoroughly.

Kellogg air compressor used. Compair Air Compressors Compair air compressors include these types of air compressors: - Variable speed rotary screw compressors - Oil-free rotary screw compressors - Fixed speed rotary screw compressors - Rotary vane compressors - Reciprocating air compressors The brand Compair is global, and has been in the compressed air, ancillary equipment for compressed air systems, and other industries - with a broad range of products - for 200 years.

Check the bar bearings at the end of each bar where they bolt to the 'spiders' (star shaped wheels). Grab the bar and twist it back and forth. There should be very little to no 'slop'- if there is, the bearings are probably shot. Check the 'idler spider' on the right hand end of the rake (for a left-hand delivery rake) by rocking it back and forth on its spindle- if it moves appreciably, the bearings are shot- about like replacing wheel bearings. Do the same with the drive spider on the other end. If it rocks back and forth, it'll probably need gearbox bearings. The gearbox should probably be filled with grease.

Even the older oil type ones will probably have enough wear in the seal that it won't reliably hold oil (and make a huge mess). Otherwise, check all the U-joints to make sure they're not bad. Grab the top of the tires and rock them back and forth sideways, to check for slop in the hubs (which run on greased bushings on the axles) and possibly bearing troubles on the offset wheel hubs. If you can, rotate the driveshaft backwards and listen for the ratchet clutches to ensure they're both free and 'clicking' to ensure both wheels will drive the rake under load.

Otherwise, check the cranks and especially the bellcrank pivots where they raise and lower the rake basket into working position. Sometimes they'll wear to the point they'll be half-sideways. The 258 I bought had rubber teeth, some original, some replacements, with a few missing.

I replaced the missing ones with TSC rubber teeth. They didn't last as long as many of the factory originals! After replacing them with new New Holland rubber teeth, I wasn't getting much better results. After that, I simply started replacing them with steel spring teeth as they went out. Most of the factory originals are also turning loose due to sheer age (this rake is probably about 30 years old). The steel teeth are IMHO MUCH more durable than the rubber teeth. Like someone else said, steer clear of the TSC steel teeth- they're cheap, but they don't hold up.

New Holland 258 Rake Manual

The only good thing is, they CAN be bent back when they bend (and they WILL bend when they hit something, make no mistake) by sticking the handle of a crescent wrench into the spring coil and pulling hard. The NH teeth are nowhere NEAR as hard as they USED to be. We used to have a 55 rake from the 50's (straight bar axle- no offset wheels like the newer 256/258 models) that the teeth NEVER bent on.

They would break occasionally, but never bend! When the spring gave out, they'd break off, and the broken end would look like broken glass because the steel was so hard! The NH teeth are tougher by far than the TSC teeth to be sure.

Later and good luck! As far as I know everything is original. But getting it from an auction its hard to say. The paint looks original. Maybe since the paint still looks good they slapped some newer decals on it?

I'm looking at a tiny picture on my phone and you're looking at the actual rake, but as soon as I saw it I thought it was repainted. Specifically, there appears to be paint drift on the tires as well as a reflective decal that was painted over next to the serial number plate. It doesn't even look like the right shade of red for a sperry machine. Of course, we aren't talking about a collector tractor. If it works and isn't rusty, it's hard to complain.